The development of Pakistan’s first 3D concrete printer by NUST students Raja Dilawar Riaz, Usama Majid, Ammar Ali, and Muhammad Faizan, under the mentorship of their advisor Dr. Muhammad Usman, offers an inevitable solution to this challenge.

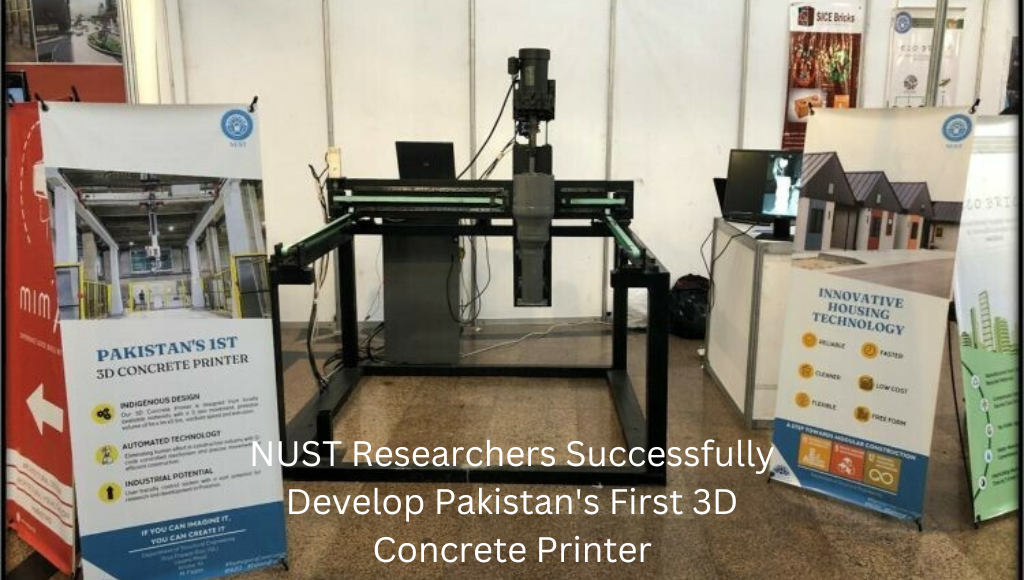

The indigenous 3D concrete printer has a frame size of 1.2m x 1.2m x 1m and can print a volume of 1m x 1m x 0.5m utilizing its 3-axis movement controlled by servos and gearboxes, a variety of nozzles (with a max size of 3 inches), continuous intake capacity, screw extrusion, and a digital control system.

Furthermore, the prototype of an inexpensive concrete printer has been developed for large-scale construction applications.

Which is capable of printing various-shaped architectural and structural components

The printer operates by creating a 3D CAD model on computer software and slicing it as per the required specifications.

Moreover, the mach3 controller reads the G-Code file and extrudes the layer of concrete, making the printing process straightforward.

And then, The printer was first showcased under the theme of “Low-Cost Innovative Housing Technology” at the First International Housing & Property Expo 2022, Islamabad, organized by the Federal Ministry of Housing and Works, Government of Pakistan.

Advantages

- Design Flexibility

- Topological Optimization

- Increased Productivity

- Reduced labor effort

- Greater research potential

- Highly precise deposition

- High-end technology-based jobs

- Multifunctionality of structural/architectural elements

- Cost-effective mass housing solution

- Energy efficient

- Promising methodology & output

- Safer construction work

- The balance between beauty, form & function